How to Build a Paint Booth Filter System

Aug 26, 2024|

Aug 26, 2024| View:26

View:26

As a painting company, these filters are creating waves in the entire segment for not just making sure that paint booths perform as required but also managing to maintain a higher level of air quality and will make it safer. Perhaps one of the most vital elements to any auto body shop is a paint booth filter system that effectively traps harmful particles, allowing for cleaner air and thus protects workers and provides better quality finishes. This piece will enlighten you on how to build a paint booth filter system.

The Evolution and Importance of Paint Booth Filters

As demands for cleaner air and better environmental compliance have grown, the paint booth filter has in turn evolved to keep up. The Importance of a Proper Paint Booth Filter System.

Air Quality Control : Overspray, dust and fumes are captured by filters so fresh air can be safely circulated to create a safer breathable environment within the booth.

Better Finish Quality: Filters reduce chances of contaminants landing on wet paint, resulting in a flawless finish.

Regulatory compliance: Efficient filtration systems support environmental regulations by minimizing volatile organic compounds (VOCs) and other pollutant emissions.

Step By Step on How to Build a Paint Booth Filter System

Step 1: Assess Your Needs

When you are working on making your own paint booth filter system, the first thing that you need to assess is what exactly you need. Consider the dimensions and type of your paint booth to calculate a corresponding filter system size. Also, what paints/materials you will be using as certain materials may require specific filters for air quality and safety.

Step 2:Selecting The Proper Filters

Choosing the Suitable Filters for your Paint Booth Filter System

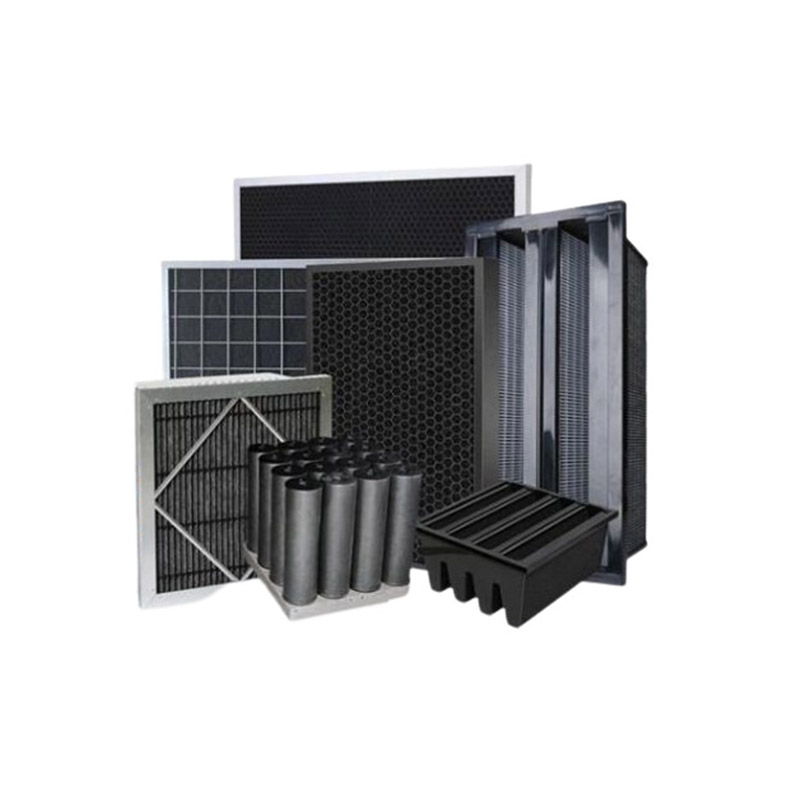

Paint Booth Filter Roll:Typically a roll to grab the bigger particles and trash as an initial line in your filter system.

HEPA Filters: High-Efficiency Particulate Air filters are necessary for the filtration of tiny particles in order to keep air clean and contaminant-free.

Activated carbon air filters: These are specifically made for neutralizing unpleasant odors and dangerous VOCs, thereby cleaning the air that we breathe.

Step 3:Filter System Layout Design

Creating an effective setup for your paint booth filter design is important to making it work properly. Use your airflow for control of contaminant capture; top to bottom and side by side are common configurations. It could very well be raining dust or pollen that can wreak havoc on your painting operation where paint booth filter rolls would need to suction at its intake coupled with HEPA and activated carbon filters designed for safe management of finer particles/gases.

Step 4:Mounting the Filtration System

Correct installation is paramount in getting the best efficiency with your paint booth filter. Check that the filter housing is securely anchored in place and well sealed at all points to prevent any scouring of air, which may spoil system operation. Moreover, structuring the system for easy filter replacement and maintenance shall further aid in upkeep thus making it operable over an extended period.

Step 5: Test the System and Monitor it

After the installation of these filters it is imperative to test and monitor your paint booth filter system vigorously through a period. It should be done in regular air quality tests to ensure that the system removes contaminants and maintains an excellent working condition. Furthermore, routine inspections that include maintenance are recommended as this is basic to proper operation and compliance with all regulations.

Finally,to have an efficient paint booth filter system, you have to make the right selection and installation of appropriate filters in addition to proper maintenance. This means using reliable filters to create a safe and compliant painting environment. If you are looking for superior and reliable paint booth filters, then get in touch with COOCA. If you choose to work with COOCA,COOCA assures the best service and products based on your requirements.

qr315@cooca.com.cn

qr315@cooca.com.cn